Q&A: B2B Customer Experience Conversation with Avnet’s Peggy Carrieres About Supply Chain Challenges, Capturing the Voice of Customer, and More!

One of the best ways to overcome obstacles is to fall back on your community and brainstorm solutions together. That’s why InMoment hosts regular Experience Exchanges to help customer experience (CX) professionals do just that.

InMoment XI Strategist Jim Katzman had the opportunity to sit down with Peggy Carrieres, Global Vice President of Sales Enablement and Supplier Development for Avnet and electronics components-industry expert.

In the conversation, she offered insight into how B2B brands can create transparency, combat supply chain challenges, redefine “customer loyalty,” and drive trust for customers who face an increasingly complex supply chain in one of the most volatile market cycles in recent history.

Our Conversation with Peggy Carrieres of Avnet

Jim: Great to see you again, Peggy! I’d like to start the conversation about the connection between the supply chain challenges many B2B companies are facing and how these challenges affect loyalty. What role does Experience Improvement play here, and how?

Peggy: I have been in this industry for over 25 years, and back then, it was all about process-focused engineering and technology—and that’s great. Still, we’ve seen the pervasiveness of electronics, and everything we use—from work to play—is packed with technology to make our lives easier.

For example, a simple light bulb used to house a filament and now has many semiconductors in it. It’s a huge industry and growing like crazy, but over time, it has gotten incredibly complex.

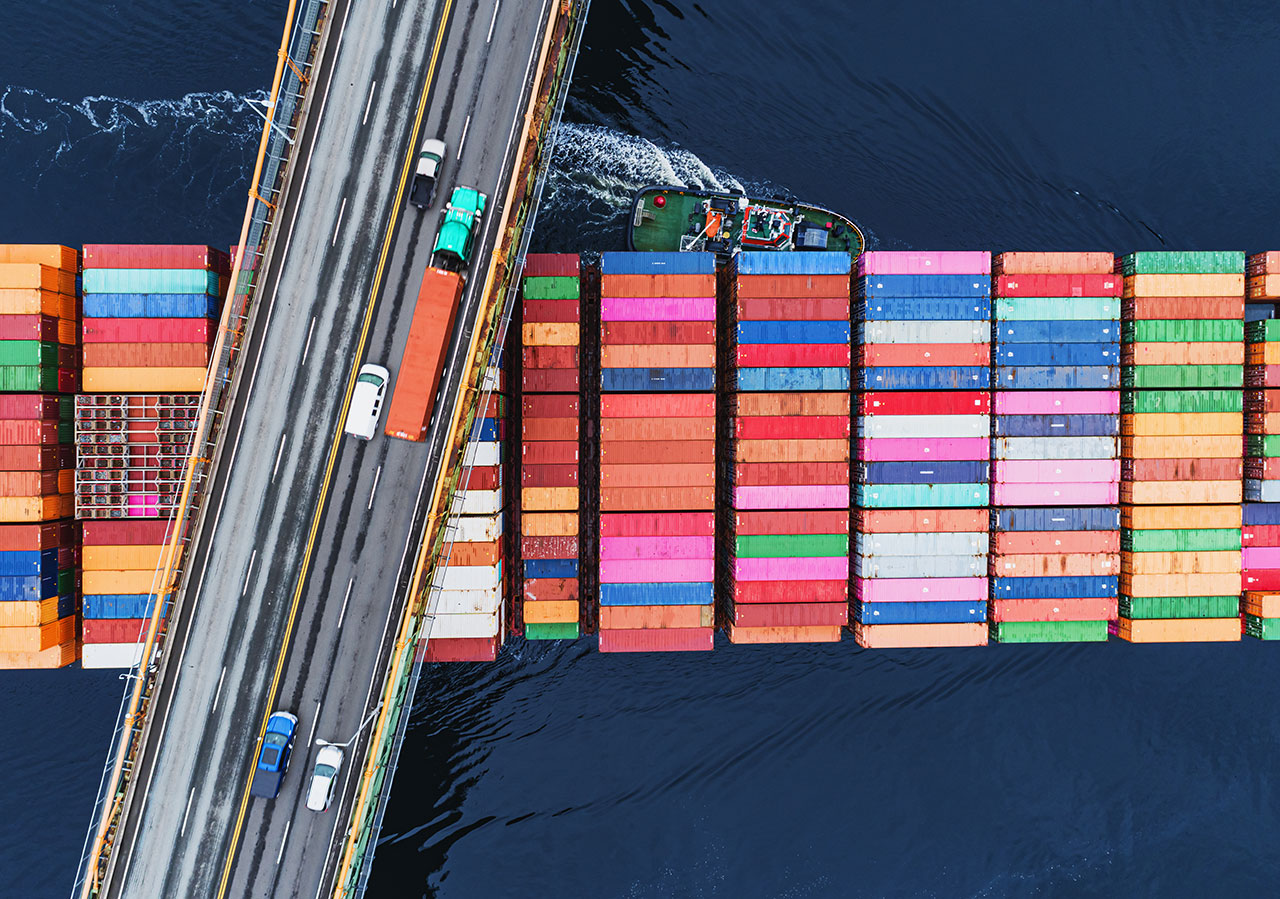

Our product goes to 40 countries to get to market, and we sit in the middle of the value chain between suppliers and customers.

We’re a value-added distributor with almost 2K engineers globally who work on designing a journey to help our customers get their products to market in a complex supply chain. But at the end of the day, what we’ve found from our trend data since we started our CX program back in 2014 is that relationships still matter. That is probably the most significant lesson in our voice of the customer journey: relationships can drive so many other factors in your business, and if you miss the boat, you are going to miss your customer.

Jim: We all know about supply chain challenges, but in the semiconductor industry specifically, can you talk about how or what role agility plays?

Peggy: It’s important to know that this industry, by nature, is cyclical; it ebbs and flows about every four years and is driven by technology. What we’re seeing today is different and more complex and has permanent changes to initially temporary solutions. Early 2020 COVID-19 hit but didn’t drive the situation yet, but as it became more and more complex, its influence grew.

Avnet is a broad-line distributor, operating in over 140 countries globally in every region. We are able to move our customer’s demands from one country to another quickly. So when you put that through a CX lens, I would say in this industry, what we’ve learned is that it’s imperative to understand global and cultural norms and how people get work done on a day-to-day basis in different cultures.

A lot of the hiccups that happen in B2B are due to miscommunication. We’ve learned that being agile through our supply chain means distributors like Avnet become the control tower, creating transparency across the full product lifecycle. If you think about it, a customer may have 300 suppliers to purchase from to get their product to market. Their demand signal can be diluted, but because we have established relationships with suppliers, we can get the early warning and adjust to be flexible in our supply chain with our clients. I don’t think this is a temporary standard; it’s going to completely change how we get business done on a daily basis.

Jim: Would you say Avnet is like a hub for those 300 suppliers?

Peggy: Absolutely, 100% I do—a global hub! We have customers who’ve engaged with us that haven’t traditionally engaged with “the channel” and who prefer or even try to go direct to the supplier, but the process is so complex it’s just very difficult. They can’t physically manage every supplier and every step of bringing their products to market, so they come to us.

Jim: Since Avnet is a global company, you have many different cultures to navigate. How do you listen for, understand, and drive action to counter the communication problems you may encounter due to those differences?

Peggy: That has been one of the most significant values of our voice of customer program. When we started it, we wanted to build a coalition in every country, but every country did its own thing and tracked its own trends over time.

It’s essential to give the feedback to someone who has context and insight into that culture. For example, we have one response that came through in Hebrew, and our translation team couldn’t translate it. So, I took it to someone who is Israeli, who works on our team here in Phoenix, and who knew the context. She relayed that the feedback was such an endearing phrase that no translation can convey its special meaning.

This experience taught me that we need global understanding and empathy across the organization. However, we also need context in regions and countries that offer nuance because it’s hard to hear those things sometimes.

We do that in a consultative manner, and by doing that, over time, our teams have been conditioned to get that feedback and use it to drive revenue and benefit, our teams have made that connection, and it has been highly successful.

Jim: How does customer experience play a role in how Avnet deals with global supply-chain challenges?

Peggy: The market will change—we are seeing signs of it now. Who the customer is can also change over time. We’re the largest revenue-generated AZ-based company, with 45% in Asia, 30% in Europe, and 25% in the US, so we’re well-balanced. But from the perspective of customer experience and relationships, we needed more.

We did a cross-correlation with NPS and what has the most uplift in “loyalty,” which is a term I hate because it can change quickly depending on how you react and respond. However, the pillars and drivers for us are ease of doing business, the quality of products and services, and, at the end of the day, how we engage with customers matters.

For instance, how we respond to a customer’s challenge will be remembered when a customer’s partnership is on the line. I am their advocate to our supplier base; being present at the table to show them I care is mission-critical. These relationships are what drive the B2B space.

Jim: Yes, I learned that when the executive escalation call comes in, you first hit mute and listen for pockets where you can fix something, even if it’s not everything. I think the key is honing your skill of listening to encompass the whole pain point and resisting the urge to jump in immediately at the first sign of distress.

Peggy: Right, and we’ve seen a complete shift in the focus of this industry. Raw materials, labor, and logistics all cost more now, and so we’ve had to change an industry’s discussion. It used to be from the total cost down to total price, but now it’s the total cost of ownership, which is the assurance of supply and mitigating risk for our client.

The conversation has shifted, and if we didn’t have a finger on the pulse of the market and work collectively with our customers, we would’ve missed the boat. If you just show a price increase without offering a conversation, you’ve hurt your relationship as well, and you don’t just come back from that.

Jim: One thing I hear from our clients is that it’s hard to capture the B2B voice. I’d love to hear how you think and process capturing that flavor in your design approach and how Avnet built its relationship survey with the employee experience in mind.

Peggy: The value of feedback is trends over time, so one thing we do (as we know who our demographics are) is we have the customers self-identify their role in the organization. We’ve got buyers, engineers, executives, and supply chain materials, and because they see the relationship differently at each level, it’s important to know the perspective behind the individual feedback.

I own our design tools and capabilities, and I focused specifically on the feedback from customer engineers. One thing that has been valuable is we ask them in a simple survey if they’d like to opt-in for a focus group, and we’ve had a pretty good response there. This volunteer participation allows us to quickly pose further and more profound questions to that group about what we’re developing at Avnet. So, I think it’s important to ask customers to self-identify because every company is different in B2B. A supply chain person in one company may be completely different from a supply chain person in another.

Another thing we are seeing is what we call “customer lifecycle convergence,” where the supply chain and design chain are becoming more integrated than ever before, so you have to be in touch with both of those voices if you want to be successful.

Jim: So, do you have different relationship questions for the different audiences you’ve identified?

Peggy: We actually just did a voice of the engineering survey, and what we found was that 93% said they spent the majority of their time looking for parts and needed someone to help them. With this, we were able to develop a new design process based on the current state of the market and trained the field application engineers to use that process.

In return, our revenue, that’s tied to what we call demand creation, has really increased over the last two years. So having that outside-in perspective and then changing the approach and the selling motion had a huge benefit for us.

That’s a Wrap!

This B2B Experience Exchange was packed with valuable insights about the supply chain challenges. Additionally, awesome employee experience insights also packed a powerful punch in this conversation, and we’ll be including those as part two! Look out for our next quarterly experience exchange, and in the meantime, check out this Guide to building a customer-centric B2B experience.